With the advancement of modern agriculture, greenhouse cultivation has emerged as a vital means to enhance agricultural productivity and ensure food safety. When constructing a greenhouse, the covering material plays a pivotal role as it directly impacts the environmental factors such as light, temperature, and humidity inside the greenhouse, which ultimately affect the crop’s growth and yield. Therefore, choosing an appropriate covering material is critical for different growers and agricultural enterprises.

This article aims to provide an overview of common greenhouse covering materials, including their advantages and disadvantages, their usage in different countries worldwide, and which groups they are best suited for – individual farmers or large agricultural enterprises. As a professional commercial greenhouse supplier, we would also like to share our experience on how to select the most suitable covering material based on practical needs and conditions, enabling you to make informed decisions.

Common Greenhouse Covering Materials and Their Pros and Cons

Different greenhouse covering materials have their own unique advantages and disadvantages and are suitable for different planting needs and environmental conditions. When choosing the appropriate greenhouse covering material, factors such as light transmittance, insulation performance, mechanical strength, and anti-aging ability need to be considered, along with specific cultivation conditions and budget constraints. Let’s take a look at the three commonly used greenhouse covering materials and explore their pros and cons, their usage in different countries, and which groups they are best suited for.

1. Plastic

As one of the main greenhouse covering materials, plastic has the advantages of low price, easy installation, and low maintenance costs. Therefore, it is widely used in personal flower cultivation and small-scale agriculture. However, its disadvantages, such as a short lifespan, poor insulation ability, and low light transmittance, are also quite obvious. In response to these issues, plastic film has been continuously improved and developed, and various composite functional films have been developed from basic materials such as polyethylene (PE), polyvinyl chloride (PVC), and ethylene-vinyl acetate (EVA) resins.

These composite functional films include long-life film, non-drip film, composite functional film, and colored film, among others. These functional films have excellent performance, such as anti-fogging, wear resistance, dust resistance, insulation, and anti-aging properties. Additionally, different types of plastic film have their own advantages and disadvantages. For example, polyethylene film has good light transmittance but poor insulation performance, while PVC film has good insulation performance but low light transmittance. Composite functional films have the advantage of multiple functions but also face the issue of higher covering costs.

| Plastic Types | Advantages | Disadvantages |

| Polyethylene (PE) | Low cost, lightweight, good light transmission, acid/alkali/salt-resistant, safe for crops | Poor insulation, weak strength, prone to tearing, may cause temperature inversion and freeze damage to crops |

| Polyvinyl Chloride (PVC) | Clear, strong, good insulation, acid/alkali/salt-resistant | Prone to dust accumulation and light degradation, low breathability and water permeability, high density, and cost |

| Functional Composite | Anti-aging, light regulation, improved insulation, extended no-drip period, and longevity | Higher cost due to multilayer composite |

| PO | High light transmission, anti-fogging, puncture-resistant, dust-proof, good insulation, high tear strength, environmentally degradable, and non-toxic | Relatively higher cost |

| Polyvinyl Fluoride (PVF) | High mechanical strength, long service life, high light transmission, dust-resistant, anti-fogging, no moss growth | Fluorine must be sandwiched in the middle layer during manufacturing to avoid environmental pollution, limited width |

Currently, the use of plastic films is more common in Asian regions, suitable not only for individual farmers but also for large agricultural enterprises. Different types of plastic films are suitable for different application scenarios, so choosing the appropriate covering material is key. Below is a table comparing the advantages, disadvantages, and parameters of different types of plastic films to help with better comparison and selection.

2. Glass

Glass is a popular choice for greenhouse covering materials due to its excellent light transmittance and stable material properties. Typically, 4mm or 5mm thick glass is used for greenhouse coverings, with 4mm being the standard in Europe and the US, and 5mm being employed in hail-prone areas. While glass offers insulation performance between that of plastic film and polycarbonate panels, its light transmittance is unrivaled.

The required accessories and sealing materials for glass greenhouses can be relatively costly. The large size of the glass adds to the skeletal load and increases the need for structural support, leading to higher overall expenses. Nevertheless, in countries and regions with limited sunlight, such as the Netherlands, glass greenhouses are widely adopted. Their advantages include durability, resistance to deformation, ease of cleaning, and an elegant appearance. As a result, glass greenhouses are well-suited for high-end flower production, research facilities, and other locations with stringent environmental control requirements. However, the steep price may limit their adoption by ordinary individual farmers.

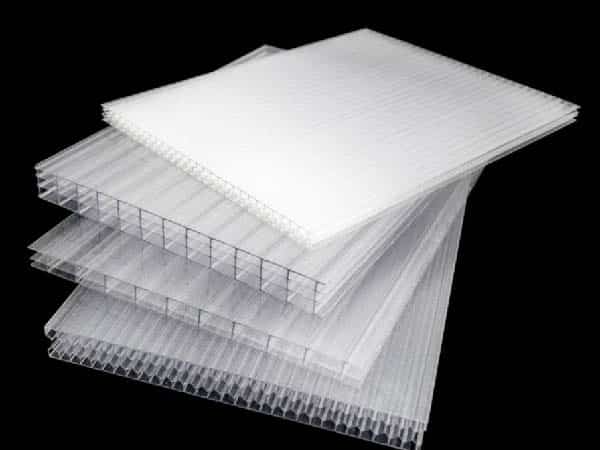

3. PC Sheet

Polycarbonate (PC) panels have emerged as a popular greenhouse covering material, gaining traction among agricultural growers and greenhouse manufacturers due to their outstanding performance. Greenhouse coverings typically use colorless transparent PC panels, available in hollow (two or three layers) or corrugated (also known as a wave) variants. These panels significantly improve the insulation performance of the greenhouse, reducing energy consumption while offering superior light transmittance and extended service life. As an innovative greenhouse material, polycarbonate panels help to lower long-term operating and maintenance costs, despite their relatively high initial investment.

The advantages of polycarbonate panels include excellent light transmittance, strong impact resistance, anti-aging and anti-UV properties, as well as resistance to high and low temperatures. These features contribute to maintaining stable temperature and humidity within the greenhouse, fostering plant growth. Moreover, polycarbonate panels are lightweight, high-strength, flame-retardant, capable of bearing substantial loads, durable, and easy to clean, maintain, and install.

However, polycarbonate panels also have some drawbacks. Their high price may not suit all agricultural growers and greenhouse manufacturers. Additionally, the transparency of the panels decreases over time, necessitating periodic replacement and increasing maintenance costs. Lastly, due to the relatively hard material, care must be taken during installation to prevent scratching or damage.

How to Choose The Right Greenhouse Covering Material?

1. Your Plants

Different plants have varying requirements for greenhouse covering materials. Some crops necessitate higher levels of photosynthetically active radiation (PAR) to ensure adequate sunlight for growth and development, while others demand superior insulation performance to maintain optimal temperature and humidity levels, thereby enhancing production efficiency.

For instance, certain fruits and vegetables, such as tomatoes, cucumbers, and peppers, require abundant sunlight to stimulate photosynthesis and improve yield and quality. Consequently, these crops generally opt for covering materials with high light-transmission properties, such as glass or polycarbonate sheets. Conversely, some root and tuber crops, like sweet potatoes and radishes, need better insulation performance to maintain stable growing temperatures and humidity. As a result, these crops often select covering materials with improved insulation properties, like plastic film or multi-wall polycarbonate sheets.

2. Climate Conditions

Selecting the appropriate greenhouse covering material necessitates taking regional climate conditions into account. For extreme conditions, such as high temperatures, heavy rain, or strong winds, materials with greater wind resistance, compressive strength, and weather resistance are recommended. For example, in tropical regions, covering materials that can block intense ultraviolet rays and mitigate temperature increases inside the greenhouse, such as transparent hollow polycarbonate sheets, should be chosen. In colder areas like Northern Europe and Canada, greenhouse coverings with excellent insulation performance, like double-layered air films, are preferred.

Moreover, varying precipitation and snowfall levels in different regions can also influence the choice of greenhouse covering materials. In areas with substantial snowfall, materials with a higher load-bearing capacity, such as tempered glass or multi-layer hollow panels, are recommended. In regions with extended rainy seasons, covering materials with superior waterproof performance, like polyethylene film or PVC film, are more suitable.

3. Cost Control and Investment Budget

Cost control and investment budget are crucial factors to consider when selecting greenhouse covering materials. Individual farmers and small agricultural enterprises may prioritize cost control, often opting for more affordable plastic films as greenhouse coverings. However, despite their low initial cost, plastic films have a relatively short lifespan, necessitating frequent replacement and maintenance, which may result in higher overall expenses. In contrast, large agricultural enterprises may be more inclined to invest in coverings with longer lifespans and better insulation performance, such as glass or polycarbonate panels, despite their higher initial cost.

Additionally, the transportation and installation costs of greenhouse covering materials should be considered. For remote locations, transporting heavier materials like glass or polycarbonate panels may incur higher costs, which should be factored into overall expenses. Moreover, the time and labor required for installation should be taken into account, as materials like glass or polycarbonate panels are generally more labor-intensive to install compared to lightweight plastic films.

4. Individual Farmers vs. Large Agricultural Enterprises

Both individual farmers and large agricultural enterprises must assess their specific needs and situations when choosing greenhouse covering materials. Individual farmers, with their smaller scale and limited investment budgets, typically opt for more affordable materials like plastic films or polycarbonate sheets. These materials are cost-effective, easy to purchase and replace, and offer satisfactory insulation and light transmission properties, meeting individual farmers’ needs to a certain extent.

Large agricultural enterprises, on the other hand, tend to select materials with superior durability and insulation performance, such as glass or polycarbonate panels, due to their larger scale and higher investment budgets.

Conclusion

As a professional commercial greenhouse supplier, we have gained invaluable experience in designing greenhouse systems. One key insight we have learned is that no single greenhouse covering material is universally ideal; instead, the most suitable material depends on various factors.