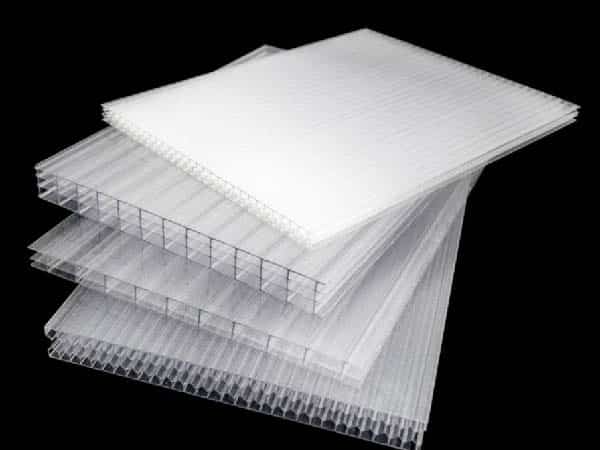

Polycarbonate sheets have recently become a popular choice for commercial greenhouses. As mentioned in our previous article, these coverings offer high strength, excellent light transmission, sound insulation, and energy-saving properties. They are crucial for enhancing greenhouse efficiency.

In this article, we will continue discussing this type of greenhouse covering. We’ll share what defines high-quality greenhouse polycarbonate sheets and how to choose them. This will help you make informed decisions to improve your greenhouse setup further.

Polycarbonate sheet greenhouses are becoming increasingly popular.

Three Essential Features of High-Quality Polycarbonate Sheets

Polycarbonate sheets are essential in modern greenhouse construction, acting as the protective “skin” of these structures. High-quality sheets improve your greenhouse’s insulation, boast anti-aging properties and are extended in durability. They also retain their color well, even after long exposure to harsh weather conditions, and are relatively low-maintenance.

When selecting top-notch polycarbonate sheets, consider these three crucial characteristics:

1. New Materials

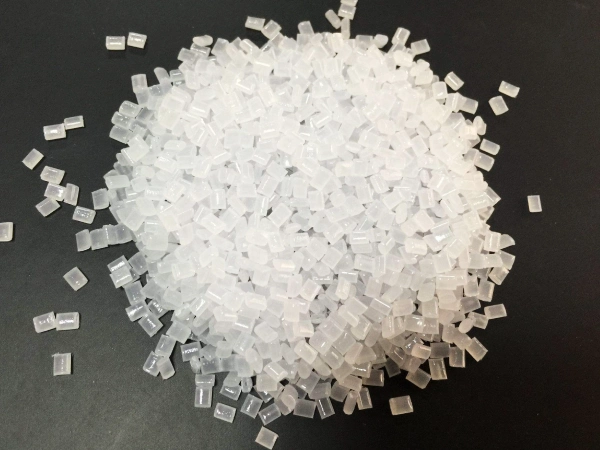

The superior qualities of polycarbonate sheets, including excellent light transmission, impact resistance, lightweight nature, flame retardancy, and resistance to sound and weather, originate from using brand-new polycarbonate materials.

Utilizing recycled materials can drastically degrade their quality, making them unfit for long-term use and failing to meet the diverse demands of greenhouse construction, which may cause future issues. Therefore, you should ensure the sheets are crafted entirely from new materials, which is critical to their quality.

2. UV Protection Layer

Exposure to UV radiation from the sun plays a significant role in the weathering of materials. UV rays cause the yellowing and deterioration of polycarbonate sheets. So, polycarbonate sheets for greenhouses usually use a UV protection layer to protect them from these damaging rays.

The sun’s UV rays can degrade about 5 microns of a UV layer yearly. With a 50-micron UV layer, a polycarbonate sheet is ensured to last at least ten years without yellowing, thus prolonging the lifespan of your sheets and reducing long-term costs for your greenhouse.

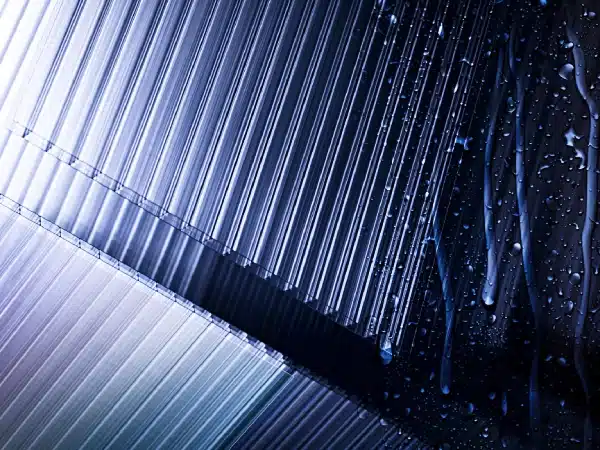

3. Anti-Drip Layer

The temperature variance between the inside and outside of a greenhouse can lead to the condensation of water vapor on the ceiling, creating droplets that diminish light transmission. These droplets might drop and harm the plants.

However, top-quality polycarbonate sheets include an anti-drip layer on the underside. This layer allows the condensed moisture to form small beads that distribute over the surface and glide down to the edges instead of directly falling onto the greenhouse crops, thereby preventing damage.

How to Choose How to Choose the Right Polycarbonate Sheets for Your Greenhouse

Once you understand the essential features of high-quality polycarbonate sheets, choosing the right ones for your greenhouse becomes easier.

Here’s a detailed guide:

Step 1. Check the Manufacturer

Ensure the polycarbonate sheets have a trademark, a specific factory address, and contact information clearly displayed. Avoid products lacking these details, as they may be of inferior quality.

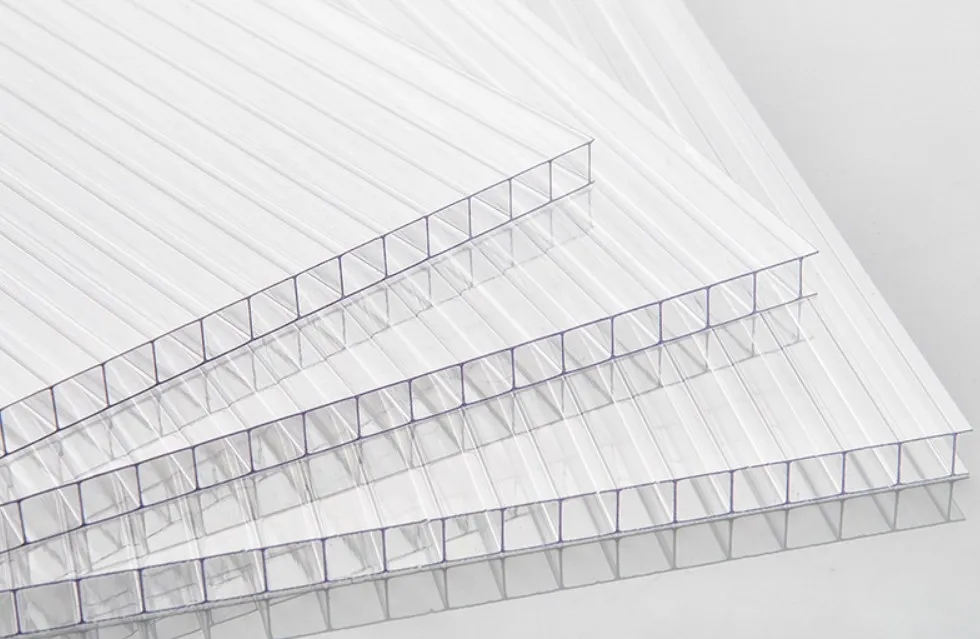

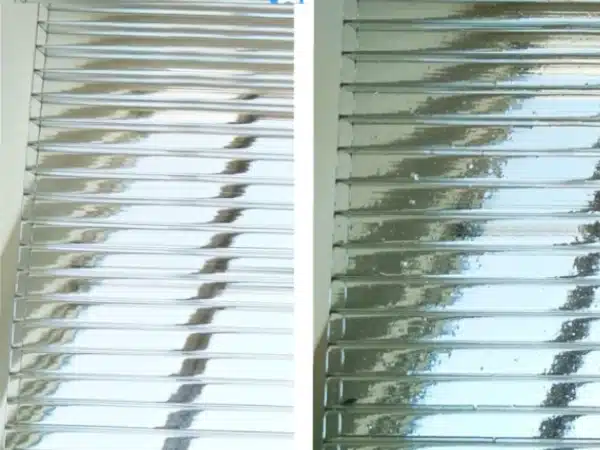

Step 2. Examine the Panel

High-quality sheets should have a light transmission rate of around 80%. If the sheets appear blurry or speckled, they may be made from recycled materials, not premium materials.

Step 3. Look at the Material

Remove the protective film and inspect the sheets for impurities and particles. High-quality polycarbonate will be clear, indicating the use of new materials. Sheets that feel gritty or visibly impure are likely made from recycled materials and are of lower quality.

Step 4. Inspect the Protective Film

The PE protective film on the sheet’s surface should adhere well without peeling. This is a sign of advanced manufacturing technology and stringent production standards.

Step 5. Check for Flatness

The sheets should be perfectly flat, indicating thick walls and robust material usage that resists deformation. Wavy sheets may suggest poor manufacturing processes or thinner material.

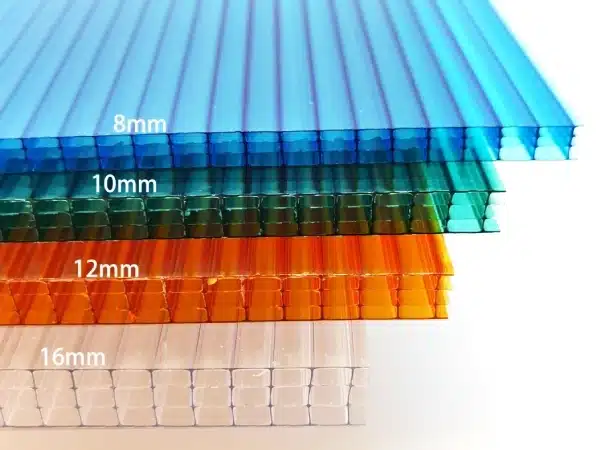

Step 6. Measure Thickness

Thicker walls mean higher material density and cost, reflecting better quality. Thicker polycarbonate sheets are more durable and provide better insulation.

Typically, panels range from 4mm to 6mm for residential greenhouses, 8mm to 10mm for commercial use, and up to 16mm for environments requiring maximum insulation and durability. The choice of thickness should consider factors such as climate conditions, the type of plants being cultivated, and the greenhouse’s heating requirements.

Step 7. Smell

High-quality polycarbonate should not emit any strong odors. An unpleasant smell could indicate the presence of impurities in the materials used.

Step 8. Test Elasticity

High-quality sheets are elastic and should snap back to their original shape without creases after bending. Roll a sheet into a cylinder and then release it. If it retains significant warping or does not return to its shape, it may be made from recycled materials.

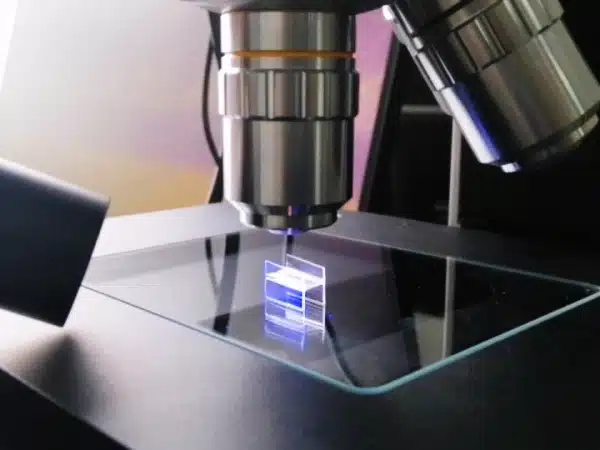

Step 9. UV Protection Layer Test

Check for a UV protection layer. Without it, sheets can turn yellow or crack after just a few months of sun exposure. If standing under a sheet feels like direct sunlight, it likely lacks sufficient UV protection.

Step 10. Ask About the Price

Compare prices among different manufacturers for the same quality and material type. Prices should be fairly consistent; if a quote is significantly lower than average, it could indicate quality issues.

The Risks of Using Low-Quality Polycarbonate Sheets

Low-quality polycarbonate sheets can significantly endanger your greenhouse’s personnel and plant life. Unlike high-quality sheets made from new polycarbonate granules, inferior sheets often incorporate scrap and recycled materials, which may contain harmful toxins. These materials pose health risks and lack the necessary impact resistance and structural integrity. This deficiency can lead to serious safety hazards.

For example, during severe weather events like hailstorms, low-quality sheets might not hold up, risking damage to the plants and animals in your greenhouse. Furthermore, these substandard sheets typically have a much shorter lifespan and are more likely to yellow and crack shortly after installation. This increases maintenance costs and introduces additional operational risks to managing your greenhouse effectively.

Conclusion

In conclusion, knowing the features of high-quality polycarbonate sheets helps us make informed choices and recognize the dangers of inferior alternatives. We encourage you not to make decisions based solely on price.

Quality should be your primary concern. High-quality materials are essential for constructing a superior smart greenhouse. Remember the old adage, “You get what you pay for.” Investing more upfront will yield greater benefits in the long run. Want to build a commercial green? Don’t hesitate to contact us for details.