Hydroponic farming has rapidly developed as an innovative agricultural method worldwide in recent years. For example, according to IBISWorld, the hydroponics industry in the United States generates hundreds of millions of dollars annually and significantly boosts local employment. On a global scale, the average yield of hydroponic vegetables per hectare is 21.89 tons, making it a viable solution for meeting the vegetable demands of arid and semi-arid regions. In this article, we’ll focus on lettuce as we explore the key aspects of hydroponic lettuce greenhouses, including their principles, construction, and management requirements.

What is a Hydroponic Lettuce Greenhouse?

Hydroponics is a soil-less plant growing technique in which the roots grow directly in a nutrient solution or an inert medium like perlite or coco coir. Lettuce is one of the most common leafy vegetables grown in hydroponic greenhouses. Farmers can optimize the growing environment by integrating hydroponics with greenhouses, resulting in modern lettuce production. This approach improves land efficiency and enables precise control of growth conditions, allowing for year-round production and a consistent supply of fresh, high-quality lettuce.

All hydroponic methods aim to optimize plant nutrient and water absorption. The most common systems include the Nutrient Film Technique (NFT), Deep Water Culture (DWC), Drip Systems, and Aeroponics.

For more information on NFT and DWC, refer to the article Greenhouse Lettuce Production. For an in-depth discussion on aeroponics, check out Aeroponic Production of Lettuce Promotes Biomass and Root Growth Compared to Hydroponic Methods.

Building a Hydroponic Lettuce Greenhouse

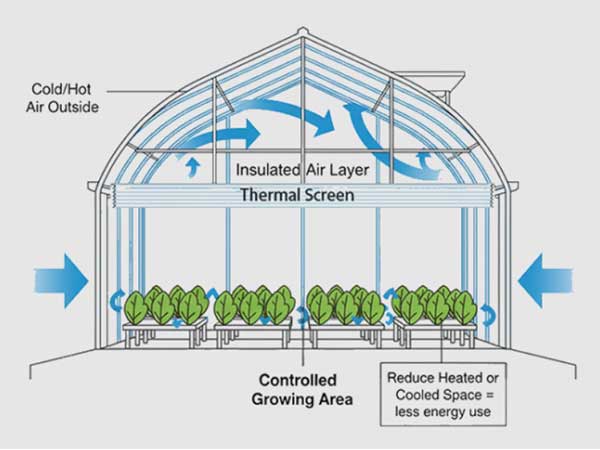

The construction of a hydroponic lettuce greenhouse is similar to traditional lettuce greenhouses. Key factors include location, orientation, scale, and drainage systems. Elements such as temperature and humidity management, lighting, and ventilation are essential to the setup. Detailed discussions on these factors can be found in our previous blog posts, such as 12 Key Factors for Building a Commercial Glass Greenhouse and the video How to Build a Commercial Greenhouse.

However, the primary difference between a hydroponic and a traditional greenhouse lies in the choice of hydroponic systems. Different systems require specific equipment, so determining which system you want to implement is the first step. Essential components of hydroponic systems include nutrient storage tanks, growing beds or channels, water pumps, piping, pH and EC control devices, and nutrient solution regulation systems. Don’t worry – professional greenhouse builders can provide detailed advice and help ensure the setup meets your needs.

Cultivation Management of Hydroponic Lettuce

1. Choosing the Right Varieties

To grow lettuce successfully, selecting disease-resistant and highly adaptable varieties is essential. Commonly used hydroponic lettuce types include loose-leaf lettuce, butterhead lettuce, Italian lettuce, Caesar lettuce, and romaine lettuce.

2. Creating the Optimal Growing Environment

Lettuce thrives in relaxed environments, with an ideal growing temperature between 15°C and 20°C. The optimal electrical conductivity (EC) for hydroponic lettuce ranges from 1.6 to 1.8 mS/cm in winter and from 1.4 to 1.6 mS/cm in summer. Although lettuce can survive in pH levels between 4.0 and 9.0, the best pH range is 6.0 to 7.0. Typically, the pH of the nutrient solution should be measured and adjusted weekly.

Lettuce grows best in winter and spring when the greenhouse temperature is between 15°C and 25°C. Below 15°C, growth slows down, while above 30°C, the plants may bolt and flower. When the temperature exceeds 25°C, it becomes difficult for hydroponic lettuce to form heads. It’s also essential to maintain the nutrient solution temperature between 15°C and 18°C.

Although lettuce requires at least 10-12 hours of light daily, studies have shown that shorter dark periods can stimulate growth. Therefore, it is advisable to use artificial lighting systems to ensure the lettuce receives sufficient light.

Table: Optimal Nutrient Ranges for Lettuce Tissue and Solution Concentrations

| Macronutrients | Tissue Sufficiency Ranges | Nutrient Solution Concentration Ranges |

| Nitrogen | 4.2 to 5.6% | 100 to 200 ppm |

| Phosphorus | 0.6 to 0.7% | 30 to 90 ppm |

| Potassium | 7.8 to 13.7% | 100 to 200 ppm |

| Calcium | 0.8 to 1.2% | 200 to 300 ppm |

| Magnesium | 0.2 to 0.7% | 30 to 80 ppm |

| Sulfur | 0.3 to 0.3% | 70 to 150 ppm |

| Iron | 168 to 223 ppm | 2 to 12 ppm |

| Manganese | 55 to 110 ppm | 0.5 to 2.0 ppm |

| Boron | 32 to 43 ppm | 0.3 ppm |

| Copper | 6 to 16 ppm | 0.01 to 0.1 ppm |

| Zinc | 33 to 196 ppm | 0.05 to 0.5 ppm |

| Molybdenum | 0.29 to 0.58 ppm | 0.5 ppm |

3. Yield and Growth Cycle of Hydroponic Lettuce

Hydroponic lettuce typically produces higher yields than soil-grown lettuce and has a shorter growth cycle. If you’re a gardening enthusiast growing hydroponic lettuce in a small greenhouse, harvesting 3 to 5 crops yearly is possible. Hydroponic lettuce can be harvested in commercial greenhouses up to 7 times yearly. In some high-tech vertical hydroponic greenhouses in China, yields have reached up to 9 harvests annually. One such greenhouse covers an area of 2,600 square meters and is currently China’s tallest vertical hydroponic facility. It has 28 vertical hydroponic racks, each with 15 layers, standing nearly 7 meters high.

4. Pest and Disease Management for Hydroponic Lettuce

Although grown in a controlled environment, hydroponic lettuce is not immune to pests and diseases. It’s recommended to use Integrated Pest Management (IPM) methods to prevent and control outbreaks. If pathogens accumulate in the nutrient solution and cause plant diseases and chemical treatments prove ineffective, you should immediately replace the nutrient solution and thoroughly clean and disinfect the entire system to ensure healthy future crops.

Advantages and Disadvantages of Hydroponic Lettuce in Greenhouses

As discussed earlier, managing hydroponic lettuce in a greenhouse offers numerous benefits. For instance, hydroponic lettuce yields are higher, grow faster, and allow for denser planting than traditional soil farming. It’s not affected by regional or climatic limitations, requires no weeding or crop rotation, and vertical hydroponics improves space utilization. All of these advantages contribute to higher cost efficiency.

However, there are also some challenges associated with hydroponic lettuce. First, the initial investment is relatively high. Setting up a hydroponic system is far more expensive than traditional soil farming. Second, diseases can spread quickly in hydroponic systems, and once pathogens are introduced, they can rapidly infect the entire setup. Third, growing hydroponic lettuce requires specialized skills and knowledge, especially regarding nutrient solution management and system maintenance. Finally, although hydroponics saves water, it consumes more electricity. Controlling lighting, ventilation, and nutrient circulation requires consistent electrical power.

Frequently Asked Questions

1. How can I prevent root rot in my hydroponic system?

Root rot is a common issue in hydroponic systems, often caused by pathogens like fungi or mold in the water. Here are a few ways to prevent it:

- Keep the water temperature between 18°C and 22°C.

- Use antibacterial agents or root-boosting microbes to protect the root system.

- Regularly clean your hydroponic system to prevent pathogen buildup.

- Use an air pump to maintain adequate oxygen levels in the water, ensuring roots get enough oxygen.

2. Why are my lettuce leaves turning yellow or wilting?

Yellowing or wilting leaves can result from various issues, including nutrient deficiencies, insufficient lighting, poor ventilation, or improper temperature. Ensure that your lettuce’s nutrient requirements are met, the plants receive enough light, and the ventilation and temperature are appropriate.

3. How do I prevent bacteria and algae growth in my hydroponic system?

Bacterial and algae growth are common issues in hydroponic systems, but you can control them with the following measures:

- Block light exposure: Algae need sunlight to grow. To prevent parts like tanks and pipes from being exposed to direct sunlight, use opaque materials or shading films.

- Change nutrient solution regularly: Replace the nutrient solution every 1 to 2 weeks and clean the tanks, pipes, and pumps to prevent the buildup of bacteria and algae.

- Use treatment agents: Special disinfectants are available for hydroponic systems that help control algae and bacteria.

- Control water temperature: Keeping the water temperature between 18°C and 22°C can slow the reproduction rate of bacteria and algae.

Conclusion

In summary, this article has provided an in-depth look into hydroponic lettuce greenhouses, including their principles, cultivation management, and advantages and disadvantages. We analyzed technical aspects, yield potential, and pest control strategies and discussed the challenges of managing such systems. The aim is to help you evaluate the feasibility of investing in hydroponic lettuce greenhouses and assess whether they can offer stable year-round production to capture market demand and maximize profits. We hope this article provides valuable insights to assist you in making informed decisions.

If you want to learn more about hydroponic lettuce greenhouses, consult INSONGREEN, a company specializing in modern agricultural greenhouse construction. We are dedicated to offering professional and cost-effective hydroponic solutions.