In modern agricultural production, the choice of greenhouse structures directly impacts initial investment and daily operational strategies. Understanding the various types of greenhouses and their characteristics is essential for both large-scale agricultural businesses and small-scale growers.

This article focuses on a modern greenhouse structure suitable for large-scale commercial use: the gutter-connected greenhouse (also known as a multi-span greenhouse). We will explore its definition, key features, cost factors, and selection tips in detail.

What is a Gutter-Connected Greenhouse?

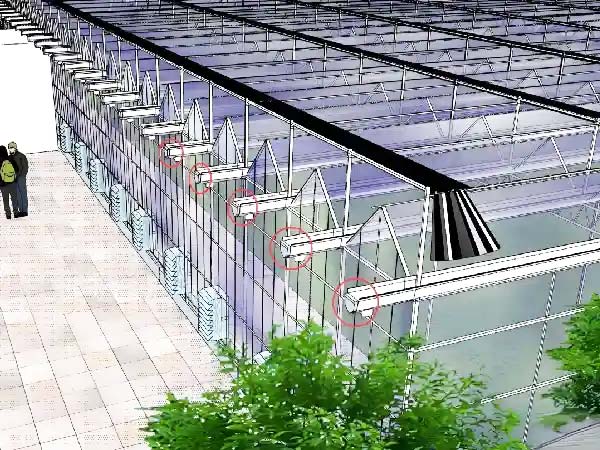

A gutter-connected greenhouse, also known as a multi-span greenhouse or ridge and furrow Greenhouse, is a structure formed by connecting multiple greenhouse units through gutters. These units are not separated by solid walls, creating an alternating “ridge-and-furrow” layout.

This design allows for flexible expansion by adding or removing units, making it ideal for large-scale commercial production, retail displays, and other purposes. While maintaining a consistent span for each unit, the height of the gutters and the materials used can also be adjusted to meet specific requirements for growing crops or displaying plants.

Gutter-Connected Greenhouse Features

The popularity of gutter-connected greenhouses in modern agriculture is largely due to the following five features:

1. High Space Utilization for Scalable Farming

Gutter-connected greenhouses maximize the use of indoor planting areas with their multi-span design. Unlike free-standing greenhouses, they do not require large spaces for pathways or empty zones between units. This leads to higher land utilization efficiency. Additionally, the spacious layout accommodates modern farming operations, such as automated irrigation and rail-based transportation systems, which help improve productivity and reduce labor costs.

2. Stable Environmental Control for Optimal Plant Growth

Compared to free-standing greenhouses, gutter-connected greenhouses have a larger internal air volume, which reduces fluctuations in temperature and humidity. This creates a more stable environment for crop growth. Strategically placed ventilation openings on the roof and sidewalls enhance airflow, and when combined with automated climate control systems, the greenhouse can lower the risk of pests and diseases, improving crop quality and yield.

3. Flexible Zoning and Large-Span Layout for Versatile Use

Many gutter-connected greenhouses are designed with minimal or no internal support columns, providing a large and open interior space. This flexibility allows for the creation of partitions or functional zones as needed, enabling the cultivation of multiple crops or gradual expansions within the same structure. Whether used for fruits and vegetables or flower production, this design supports unified management and control across the greenhouse.

4. Efficient Drainage and Ventilation Systems

The gutter system in these greenhouses not only integrates multiple units but also ensures efficient rainwater collection and discharge:

External Drainage: Gutters are installed at the ends of the greenhouse, with a gutter endcap (approximately 400mm in length) connecting to a downspout (about 100mm in length). These downspouts are linked to the main drainage system. External drainage is simple to install and highly effective.

Internal Drainage: In this setup, drainage pipes are installed inside the greenhouse along the gutter ends, requiring perforations for pipe connections. While installation is more complex, internal drainage is advantageous in colder regions, such as northeastern China, where pipes remain inside the greenhouse, preventing freezing and ensuring smooth water discharge.

In addition, ventilation openings on the roof and sidewalls work in tandem with the gutter drainage system. This allows rainwater to flow out quickly while improving airflow inside the greenhouse.

5. Strong Load-Bearing Capacity for Changing Weather

In gutter-connected greenhouses, gutters serve more than just a drainage function—they also support structural loads. During roof installations or maintenance, gutters can act as temporary walkways. Depending on the region’s snowfall and wind loads, structural enhancements to the gutters and roof can be made. This ensures the greenhouse remains safe and stable during extreme weather events such as heavy rain, snow, or strong winds.

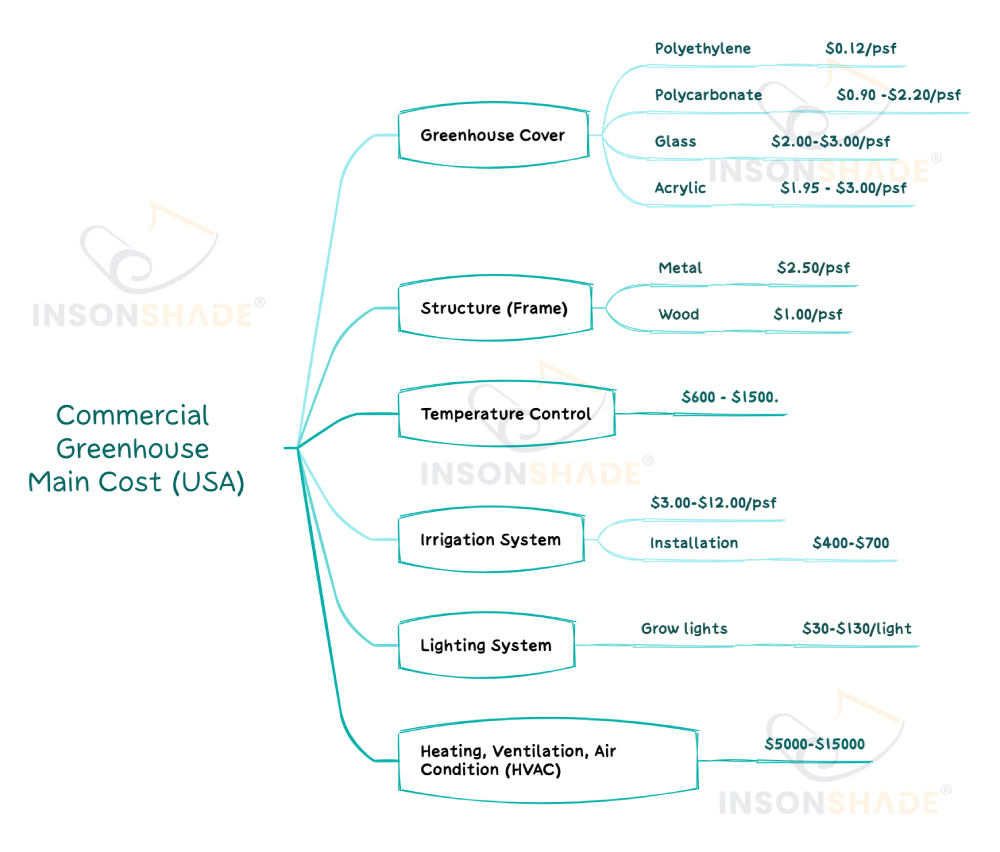

Cost of Gutter-Connected Greenhouses

The cost of a gutter-connected greenhouse depends on several factors, including the choice of materials, supporting systems, greenhouse size, and design complexity.

For example:

- Frame Materials: Galvanized steel frames are more expensive but offer superior durability and load-bearing capacity. In contrast, plastic film is more affordable but requires regular replacement.

- Supporting Systems: Add-ons like irrigation systems, temperature control systems, or IoT solutions can significantly increase the overall budget.

- Design Complexity: Large-span or multifunctional designs often require more precise structural engineering and higher construction costs.

Additionally, costs vary by region due to differences in logistics, labor, and market demand. For instance, construction and production costs are generally lower in Asian markets, whereas local supply chains in North America or Europe offer advantages in delivery speed and after-sales support.

When planning your budget, it’s essential to consider all aspects of production, logistics, design, and installation. Proper resource allocation can help manage costs while maximizing profitability. For more detailed discussions, refer to our other articles on the cost of commercial glass or gutter-connected greenhouses.

How to Choose the Right Gutter-Connected Greenhouse

Choosing the right gutter-connected greenhouse requires careful consideration of your budget, planting needs, and the reliability of suppliers. Below are some key factors to help guide your decision.

1. Budget Planning

Your budget plays a crucial role in determining the size and features of your greenhouse. If you’re starting small or have limited funds, consider a basic design that meets your immediate planting needs. These greenhouses can be upgraded later with advanced systems as your business expands. On the other hand, if you’re planning large-scale operations, it’s wiser to invest in a high-specification greenhouse from the start. This approach ensures greater production efficiency and smoother operations in the long term.

2. Planting Needs

It’s important to align your greenhouse choice with your crop’s value and requirements. For low-value crops, a simple and practical greenhouse design will suffice. However, if you’re growing high-value crops like fruits, vegetables, or flowers, you’ll need a greenhouse equipped with advanced environmental control systems. Features such as shading systems, automated irrigation, and precise temperature control are essential for achieving optimal growth conditions, improving crop yield, and ensuring high-quality output.

3. Customization Options

Customization allows your greenhouse to better meet your operational needs. For example, the choice of covering materials should depend on your local climate and crop requirements. If your greenhouse is in a cold region, the gutters should be made of thicker, more durable materials to handle the added weight of snow. Conversely, in warmer regions, lightweight materials might be more appropriate. In addition, other internal system configurations, like gutter positioning for drainage or enhanced structural supports, should also be tailored to your specific needs.

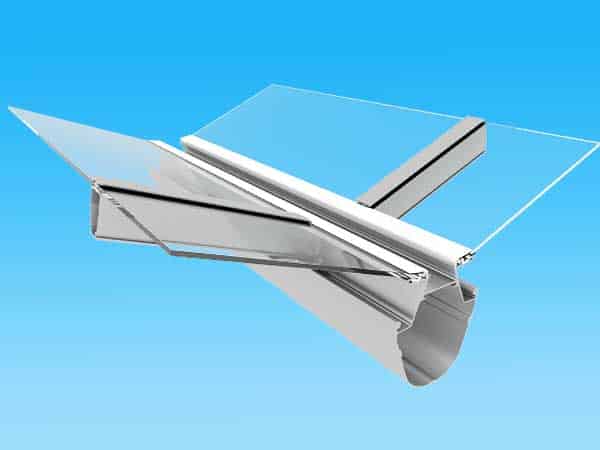

How to Choose The Gutter Materials

The defining feature of a gutter-connected greenhouse is its interconnected structure, making the choice of gutter materials especially important. Here are the key factors to consider

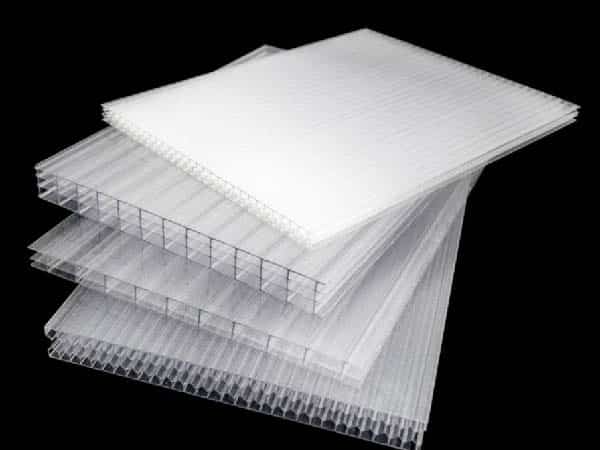

1. Gutter Thickness

The thickness of the gutter plays a crucial role in ensuring its load-bearing capacity. Gutters made from galvanized steel typically range from 1.5mm to 3.0mm in thickness, with specific requirements depending on the greenhouse’s roof covering material and regional climate conditions. For example, thin-film greenhouses often use gutters with a thickness of 1.8mm or 2.0mm. In contrast, glass-covered greenhouses or those with polycarbonate panels require thicker gutters to handle the added weight. Choosing the right thickness ensures the greenhouse can withstand various weather conditions, such as heavy rain or snow.

2. Zinc Coating Thickness

The thickness of the zinc coating directly affects the gutter’s rust resistance and overall lifespan. Zinc coatings typically range between 80g and 120g. Since it is difficult to visually assess the quality of the zinc layer, it is critical to source gutters from reputable suppliers to ensure long-term performance and durability.

3. Precision of Bending Angles

For greenhouses with glass-covered roofs, the accuracy of the gutter’s bending angle is another vital consideration. Aluminum ridge beams must be cut to fit tightly against the gutter’s angle. If the bending angle is imprecise, it can cause significant issues during installation, such as misalignment, increased labor costs, and longer construction timelines. Ensuring precise bending angles is essential for reducing installation challenges and improving overall efficiency.

Gutter-Connected Greenhouses VS. Free-Standing Greenhouses

To help you quickly understand the differences between gutter-connected greenhouses (multi-span) and free-standing greenhouses (single-span), here’s a detailed comparison based on various dimensions.

Below is a table summarizing the key differences:

| Dimension | Gutter-Connected Greenhouse (Multi-Span) | Free-Standing Greenhouse (Single-Span) |

| Environmental Control |

|

|

| Heat Retention & Energy |

|

|

| Land Utilization | No large gaps between units, maximizing land use. | Requires additional space between units for pathways, lowering land efficiency. |

| Internal Space Utilization |

|

|

| Expansion & Zoning |

|

|

| Multi-Crop Cultivation | Requires additional construction (e.g., partition walls) for growing multiple crops in separate zones. | Naturally separated units make multi-crop farming easier but less efficient for land and equipment utilization. |

| Labor & Operational Costs |

|

|

| Transportation & Loading |

|

|

| Structural Considerations |

|

|

| Investment Costs |

|

|

From the comparison, it’s clear that gutter-connected greenhouses excel in areas like environmental control, land utilization, and automation capabilities, making them ideal for large-scale, intensive farming. However, their higher construction costs and structural requirements make them a significant investment.

On the other hand, free-standing greenhouses are better suited for small-scale, diversified production models. While they are more affordable to build, they come with higher long-term energy and labor costs. Ultimately, the choice depends on your budget, crop types, and production goals.

Conclusion

The gutter-connected greenhouse stands out as the preferred choice for agricultural producers and commercial venues seeking large-scale, automated production. Its multi-span design, energy efficiency, and superior drainage capabilities make it ideal for projects focused on rapid expansion and long-term operations. Although the initial investment may be higher, this greenhouse offers unmatched advantages in operational efficiency, scalability, and maintenance, making it a cost-effective solution over time.

For more detailed insights or a tailored design and construction plan, feel free to reach out to our professional greenhouse service team. We are dedicated to helping you achieve the perfect balance between agricultural performance and business goals, enabling sustainable, efficient, and competitive farming solutions.